The correct lubricant

NOTICE

After 50 years, including 30 with Mobil Oil and Engen, I am retiring. What I am leaving behind is available to anybody who wants it. It is free.

***

(1) Textbook and ready reference book 'The correct lubricant'(2.1 Mb)

and the Word version of the book for updates(3.7 Mb)

See contents and summaryof 'The correct lubricant'

See comments about the book

***

(2) The two-day workshop based on the textbook has a fully illustrated presentation(18 Mb)

See suggestions concerning the workshop

***

(3) Links for easy access to 3049 relevant web pages which include illustrations and additional information. See below.

(Petr Vavruch does not always agree with all the views expressed in these web sites.)

You can let me know

if some of the web pages no longer work - or if some wonderful articles should be added.

The code of this web page is simple, you can get it by the right click and selecting 'View page source'.

***

All this will remain available for the time being but not forever. If you want to be safe, make your own copies.

***

To say lubrication is important is an understatement. The role of lubrication in reducing friction, cooling, minimising wear, improving efficiency and avoiding unplanned downtime is as critical as the design or componentry of any machinery.

Aaron Stone

Estimates show that between 2 and 4 percent of an industrialised country’s gross domestic product (GDP) is lost through friction and to mechanical parts wearing out.

Pleth Nielsen

NEWS

Precision lubrication (the latest issue, December 2023)EU Parliament’s Euro 7 vote a step forward, but not enough, says ACEA (15 October 2023)

API adopts SAE 0W-8 and SAE 0W-12 (28 September 2023)

The Truck and Engine Manufacturers Association has formally requested a new engine oil performance category, known as PC-12 (September 2023)

Lubrication challenges for fuel-agnostic engines (15 June 2023)

ILSAC revises request for a new ILSAC GF-7 oil category (3 May 2023)

PC-12 moving ahead, latest updates (20 March 2023)

Gasoline quality lags behind needs of direct-injection engines (21 February 2023)

Search continues for Mack T-11 engine test replacement (10 August 2022)

Dr Neil Canter - Carbon dioxide removal using an electrochemical cell (June 2022)

Infineum launches single oil solution for MAN B&W two-stroke engines (19 May 2022)

IFC’s new global engine oil specifications under final review (2 May 2022)

Infineum - On the road to PC-12 (March 2022)

Dr Yulia Sosa - Hydrogen-powered vehicles: Is the third time the charm? (April 2022)

Engine oil specifications: What’s next? (9 February 2022)

Exol Lubricants is approved for Scania’s new gearbox oil spec (17 November 2021)

Cummins begins tests of hydrogen-fueled internal combustion engine (13 August 2021)

David Tsui - The International Fluids Consortium (IFC), a newly formed industry body led by automakers (10 May 2021)

Afton launches world’s first e-transmission fluid additive (2021)

World’s most powerful tidal turbine launched (28 April 2021)

Shell to conduct trial of hydrogen fuel cells for ships (26 April 2021)

Mike Kunselman - Does new OEM global fluids consortium spell end of ILSAC? (14 April 2021)

Christoph Rofka, Deepak Davendrappa, Jacob Sterlin, Rashpal Bhatti - Marine diesel engines: The beginning of the end? (23 February 2021)

Proposed ASTM standard aims to provide accurate information on hydrocarbons (2 November 2020)

Castrol launches new pre-oil change treatment product (2020)

Breakthrough diesel exhaust fluid (2020)

Dr Raj Shah, Dr Hind Abi-Akar, Stanley Zhang - Modern global engine oil standards (September 2020)

STLE presentations by Afton, Croda, Evonik, ExxonMobil, King Industries, LANXESS (prev, Ciba), Münzing, Lubrizol (November 2019)

Japan’s ultra-low viscosity passenger car motor oil specification GLV-1 will impacts base oil quality demands (14 April 2020)

The International Maritime Organization (IMO) has approved and adopted a comprehensive set of guidance and guidelines to support the consistent implementation of the lower 0.50% limit on sulphur in ships' fuel oil (19 July 2019)

GE exits locomotive business, sells division to Wabtec (25 February 2019)

Mazda Motor to launch world’s first commercial gasoline engine to use compression ignition (9 August 2017)

SUBJECT LINKS FOLLOWING THE SECTIONS OF THE TEXTBOOK

Lubrication - general1. Three basic aspects of lubricating oils

1.1 Viscosity, kinematic, dynamic, ISO VG

1.2 and 1.3 Viscosity of engine oils and automotive gear oils, SAE, multi-grade

1.4 Viscosity index, viscosity modifiers, viscosity-temperature chart, calculators

1.5 Pour point, pour point depressant

1.6 Flash point and Noack volatility

1.7 Charts, blending

Answers to 1.7 (link)

1.8 Foam, entrained air and air release, defoamant, cavitation

1.9 Base stocks, saturates, aromatic hydrocarbons, API groups

Lube oil reclamation and re-refining

1.9.1 What does 'synthetic' mean?

Synthetics - usage

1.9.2 Polyalphaolefins (PAO)

Food-grade lubricants

1.9.3 Other synthetic hydrocarbons

1.9.5 Polyalkylene glycols (PAG) (polar compounds)

1.9.6 Esters, amides, environmentally friendly lubes

Vegetable oils and biodegradable lubricants

1.9.7 Naphthenics

1.10 Oil performance, performance additives

1.11 Water separability (demulsibility)

1.12 Supplemental ('proprietary') additives

2. Answers to REVISION 1 (link)

3.1 Engine oils, detergents, dispersants, ZDDP, fuel economy

Friction, wear and failures

Sludge, drain intervals, maintenance

3.2 Engine oil specifications, API service categories

3.3 and 3.4 Sulphated ash, TBN

3.5 ILSAC (International Lubricant Standardization and Approval Committee)

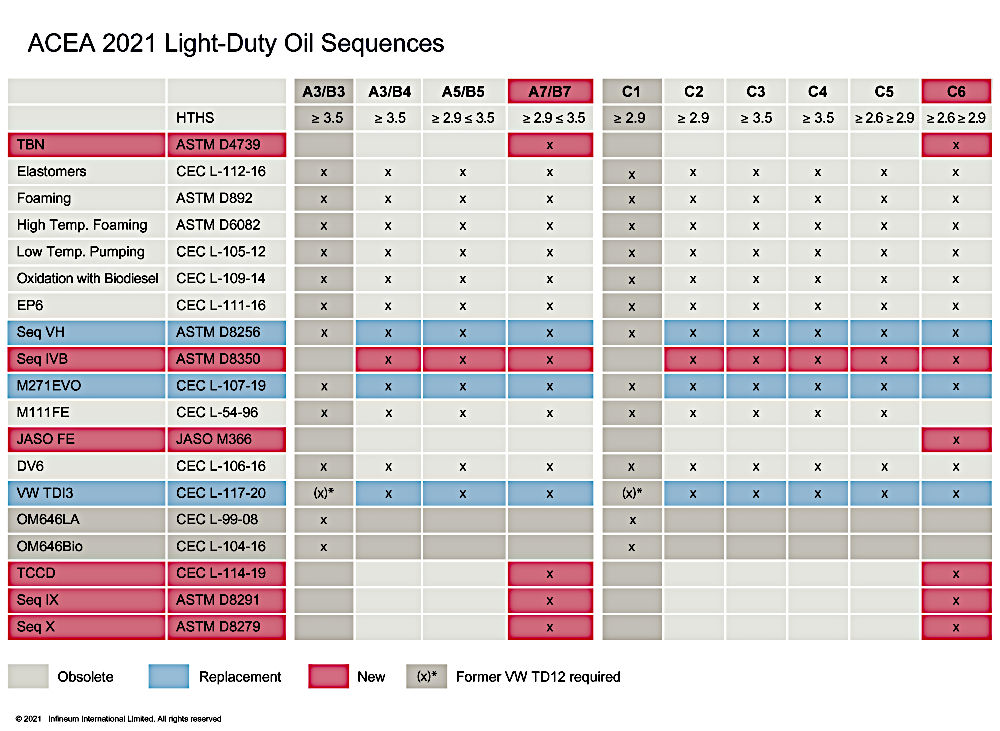

3.6 ACEA (Association des Constructeurs Européens d'Automobiles) and Equipment Manufacturers (OEM)

General Motors dexos

3.9 Two-stroke petrol engines

3.10 Outboard motor oils

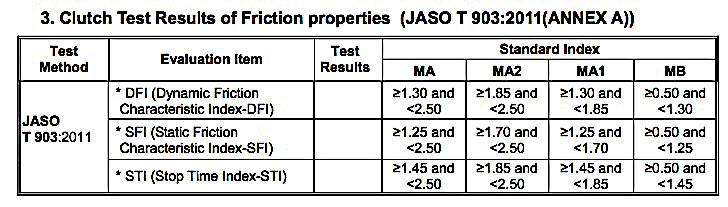

3.11 Motorcycle oils

Electric vehicles, hydrogen combustion

3.12 Gas engines

3.13 Marine engines and emergency power generation, marine lubes and fuels. Locomotives

3.15 Jet engines and gas turbines

3.16 Automotive gear oils for manual gearboxes

3.17 Limited slip differentials

3.18 and 3.19 Eaton (form. Fuller) and ZF-FreedomLine, Caterpillar

3.20 Allison

3.21 Total Acid Number (TAN)

3.22 Automatic transmission fluids (ATF)

3.23 Farm equipment oils, UTTO, STOU

3.24 Brake fluids and coolants

4. Answers to REVISION 2 (link)

5. Lubrication conditions, EHL, anti-wear, EP

Graphene, nanomaterials, 2D solid lubricants

6. Industrial gear oils

Micro-pitting, wind turbines and using synthetics in gears

6.1 Worm gears (PAG)

6.3 Open gears

Gear failures

Chain and wire rope lubrication

7. Greases (also 7.3, 7.5 and 7.7)

Grease guns and systems

7.1 and 7.2 Grease thickeners, polymers and compatibility

7.4 Grease lubricated rolling element bearings

7.6 Grease-filled gearboxes

7.8 Grease or oil?

8. Bearings (also 8.2)

Paper machines, spindle oils, sugar mills, Morgan and Danieli

8.1 Rolling element bearings

Rolling element bearing failures

8.4 Steam turbines, varnish

9.1 Air compressors, coalescer filters

9.2 Vacuum pumps

9.3 Compressors for other gases

9.4 Refrigeration compressors

10. Hydraulic fluids

10.1 Fire-resistant fluids

10.2 Oil cleanliness

Particle counting, purifying oil, preventing contamination

Oil filters

Flushing

11. and 13. Lubricant storage and storage life (shelf life)

12. Transformer oils

14. Machine tools

15. Cutting fluids, metal cutting, grinding

16. Rust preventives, stored machines

17. Answers to REVISION 3 (link)

Hint No. 2 for CHALLENGE (link)

Hint No. 3 for CHALLENGE (link)

18. CHALLENGE solution (pdf)

Answers to questions (link)

Oil suppliers' information, approved and recommended lubricants (for information only)

Maintenance, lubricant monitoring, sampling and analysis (in the following sections)

Monitoring equipment without special instruments and without laboratory samples

Designing oil analysis programme, standard test methods

Condition monitoring

Oil and grease sampling

Sampling frequencies

Advanced test methods

Ferrography

Root causes of failures, analysis interpretation

Grease analysis

Oil cleanliness

Particle counting, purifying oil, preventing contamination

Oil filters

Flushing

Water contamination

Fuels

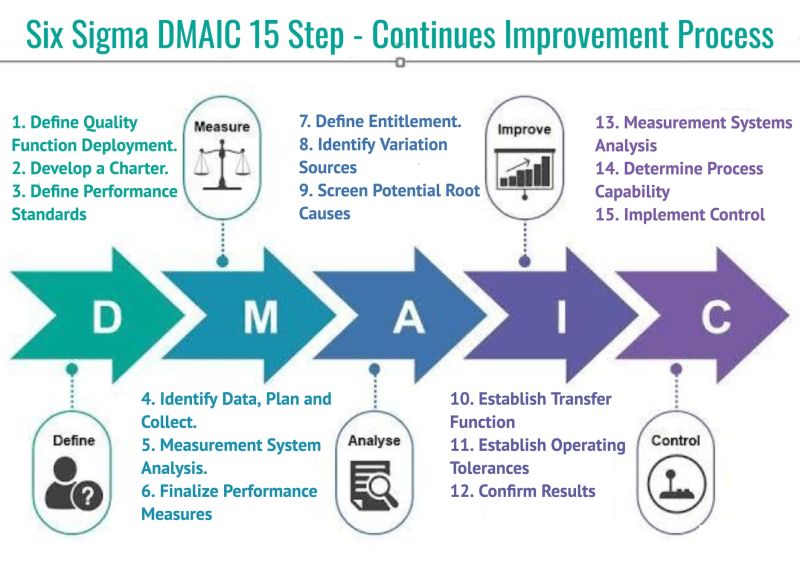

Maintenance strategies - reactive, preventive, predictive, proactive and prescriptive

Management, maintenance management, Total Productive Maintenance, autonomous maintenance

Reliability, RCM

Maintenance/Industry 4.0, Internet of things (IoT), AI, CMMS

Lubrication practices, lubrication excellence

Training, education, skills

Light reading

Lubrication - general

Lubrication explained (videos)Ali Ghanbarzadeh - Tribochemistry (2020)

ExxonMobil - Nine things you might not know about lubricants (2019)

tribonet - Tribology Wiki

Test your knowledge: 3 questions

Mark Barnes - How to squeeze every last cent from your oil (2003)

The lessons we learn through struggles, mistakes and failures (2022)

Jeremie Edwards, Noria - 3 quick lubrication wins (22' webinar, 2022)

Top 10 things you (maybe) didn’t know about lubrication (20´ video, 2015)

Steven Sanchez, John Wallace - Lubrication

Petr Vavruch's 60 minute presentation

Petr Vavruch's presentation

Petr Vavruch: Extending zinc-containing turbine oil life (presentation, 2001)

The correct lubricant (presentation)

Starfire - Guide to mitigating lubricant supply chain issues (2022)

Lubricants; Tribology

tribonet - Introduction to Tribology (video 4:26, 2021)

Riya Veluri, tribonet - Oil lubrication (2022)

Dr Gamini Amarasekera - Overview of lubricant technology (2010)

Lubrication basics

Afton - Basics of lubrication (video 10:47)

Principles of lubrication (sample video)

Lubrication and beyond (brief)

TestOil - Lubricant fundamentals

Lubricant fundamentals Part 1 (video 13:42)

Lubricant fundamentals Part 2 (video, additive introduction is in Part 1)

Jane Marie Andrew - Lubrication fundamentals: Understanding the oil, equipment and operating conditions (2019)

NiMAC calculators

tribonet - Tribology calculators (2023)

Dr Nancy McGuire - Lubrication challenges in the wind turbine industry (2019)

5 Lubrication myths that are costing you money

Randy Carlisle - Myths and magic of lubricating oil management in rotating machinery (41' video, 2021)

How lubricants work I (video 4:44)

How lubricants work II (video 6:43)

Avoiding metal-on-metal surface contact

Lubrication and greasing: working principle (brief)

Amin Almasi - Lubrication of small/medium machines and bearings (2021)

Wes Cash - Best practices for wheel-end lubricants (2018)

Overcoming the most common lubrication misconceptions

Articles by Manoj

TLT archives

Lube Media Digital Exclusives

Noria - Short videos

Noria - More short videos

Alejandro Meza - Selecting lubricant based on specifications (in general, 2016)

Acculube - Tech talks

CSC - Library

Lubrication Engineers - Articles

Machinery Lubrication - Tips and articles (2017)

Tribonet

Tribonet - How lubricants work (short video)

Plant services - On-demand webinars

What's hot? Current trends in lubrication and oil analysis

Ten hot lubrication trends

Maintaining lube oil quality (2009)

5 ways poor lubrication can cause problems (2018)

Jim Fitch: Be alert to heat as both a contaminant and a symptom (2018)

Noria - How to extend oil life (short video 2017)

RELIABLEPLANT videos

Elba LUBE-INFO

Klüber articles, e.g. Bearing lubricating procedures

Lubrita - References

Rexnord - Library

STLE - Archive

TestOil - Knowledge center

Lubes'n'Greases (incl. Additives)

Learn Oil Analysis - Articles

Articles by Riya Veluri

Learn Oil Analysis - Resources

Elite Lubrication Specialists - Blog (WARNING: SCARY! short vide, 2018

UE - Lubrication resources and information

Various lubrication systems (2016)

How to select a lubrication systems (2017)

Jim Fitch - Add oil circulation to gear and bearing sumps for greater reliability (2013)

Garrett Bapp - Best practices for topping up small sumps and reservoirs (2017)

Jim Fitch - Managing the perils of short-volume oil changes (2017)

Dan Holdmeyer - Air mist lubrication (2023)

Lubricating equipment catalogue

General Petroleum - Various classifications

WearCheck Africa - FAQ (2020)

DES-CASE - Glossary (also engine, hydraulics, pneumatics)

Cepsa - Glossary

TestOil - Glossary

Glossary of terms

MOSIL - Glossary

Oil industry abbreviations

Afton - Acronym glossary

Infineum - Acronym glossary

TWC: Three-way catalyst, used for reducing toxic emissions from petrol engines

Engineers EdgeWestmoor - European Lubricants Coding: ISO 6743

Chevron Marine - Technical bulletins

Croda literature

KEW Engineering - Articles

Power Transmission Engineering - Articles

Machinery Lubrication - Articles

Machinery Lubrication - Subscribe

Oil specifications - Articles, references

Precision lubrication - Articles

Trico Corp - Articles

The Five Rights of lubrication

Garrett Bapp - Why you should maintain precise oil levels in sumps and reservoirs (2017)

Choose the right lubricant to reduce air pollution (2017)

Why oil goes bad (2008)

Break-in wear (short video)

Five common lubrication problems and how to fix them

Dr Nathan C. Wright - 3 causes of unreliable equipment and how to eliminate them (2018)

The hidden dangers of lubricant starvation

Heinz Bloch - Lubrication best practices (2019)

The 100 failure modes of lubrication and lubrication programmes (2014)

How to define a lubrication failure (short, 2017)

Jim Fitch - Lubricant consolidation: steps and benefits (2011)

Cross-reference of branded automotive lubricants (2020)

How to go about consolidating your hydraulic oil inventory

For example, your hydraulic equipment uses the following array of oils:

Warren R&O, Conoco MV-22, NAPA AW-46 and AW-315.

Effectively, this user has both R&O and anti-wear hydraulic oil in THREE different viscosity grades - one of which is high VI. 315 mens 315 SUS at 100 degrees Fahrenheit, which is roughly equivalent to ISO 68.

I'd be looking at probably an AW-46 to cover his entire fleet. But to confirm this, I would first assess each piece of equipment using the procedure and worksheets in my advanced hydraulic maintenance blueprint:

http://www.hydraulicsupermarket.com/blueprint.html

Once that's done and the "standard" oil selected, the next issue to consider is how to go about changing equipment over to the standardized oil.

The first thing to understand is you ain't going to get any peace of mind from the oil companies. It's highly unlikely that any oil blender will tell you it's OK to mix their oil with a competitors.

And for good reason too. When oils with different additive chemistry are mixed, there is always a risk of additive 'drop-out'.

At the very least, you should be doing a thorough oil drain and filter change as part of switching oils. But unless it's practical or possible to drain every part of the system, a small percentage of the original oil will remain and be mixed with the new oil.

If the old and new oils have different base stocks, possible swelling or shrinking of seals may need to be considered. And a DOUBLE oil and filter change may be advisable.

This involves an initial oil drain and filter change. The system is then filled with the new oil to the minimum level required and the oil circulated until it's been turned over at least five times. The oil is then drained and the filters changed a second time.

Regardless of which method is used, before making the switch, it's a good idea to mix equal parts of the original and new oil in a glass jar and shake vigorously.

Wait half an hour and observe the solution. Look for changes in color, clarity, viscosity and sediment. If in doubt, or for extra peace of mind, filter 100 millilitres of the old, new and mixed oils through a patch filter - noting the time taken for each. If nothing abnormal is observed, then it should be safe to proceed.

Brendan Casey

Are you using the wrong oil?

A Q&A guideline for purchasing lubricants (2007)

Dave Wooton - How to evaluate a new lubricant (2017)

Travis Richardson - How to implement a lubrication quality control process (2021)

Start with clean: lowering total costs with lubricant reception and storage (2022)

Greg Fernandez, Chevron - Best ways to evaluate lubricants (2019)

Purchasing lubricants based on performance

Dr Mary Moon - Radiation resistant lubes (2022)

Selecting the right lubricant supplier

Jeremie Edwards - 3 red flags in lubricant supplier agreements (short, 2021)

How to transition to a new lube supplier

How lubricant suppliers impact machine reliability

Why and how to test new oil deliveries (2017)

TestOil - Lubricant compatibility testing (video, 2020)

TestOil - Compatibility testing (2022)

Vincent Bouillon - How to check the compatibility of hydraulic fluids through laboratory testing (2021, might require registration)

TestOil - Lubricant compatibility testing (2020)

TestOil - Compatibility testing sample results (2020)

Hazards of changing lubricant brands

Effects of lubricants mixing in a machine

DES-CASE - The downstream effect of lubricant contamination and the value in controlling it (video)

Lubrication for hire: Is contractor-based lubrication right for you?

Advantages of contracting out your lubrication programme

How to manage lubricant waste and disposal

Jim Jung - Track your lubricant’s journey to optimize machine health (2018)

Mobil - Using UV dye for leak detection

Jim Fitch - Standby equipment oil monitoring and maintenance (2005)

When to use an oil heater (2016)

Wikipedia - What is REACH?

EU modifies lubes ecolabel standard (2019)

Lauren Groff - Guide on writing an effective occupational health and safety (OHS) policy statement

Michael C. Brown - Lubricant toxicity (2016)

Bennett Fitch - What to know about safety data sheets (SDS) (2021)

Apple Rubber - Seals (2018)

Efunda - Seal material compatibility

Seal material compatibility

Dr Hermann Josef Stolz, Dr Wilhelm Huber, Dr Martina Mennicken-Meuthen, Denise Weber - Seal material compatibility

Parco - Elastomer selection guide (2013)

Parco guides

Timken - Guidelines for bearing seals

Garrett Bapp - Practical guide to lip seals (2016)

Michael C. Brown - Wiper seals in hydraulic systems (2017)

Cooper Standard - Seal materials

Advantages of labyrinth seals (2013)

Hydraulic fluid temperatures above 180F (82 °C) damage most seal compounds and accelerate degradation of the oil.

Brendan Casey

How to mitigate contaminant ingression in hydraulic systems (2017)

Best practices for waste oil management

Reclaim and recycle used oil (2015)

Brain Ramatally - Strategies for decontaminating and reclaiming your in-service lubricants (2022)

The importance of the colour of engine oil in marketing (LnG EMEA October 2018)

Wikipedia - Diesel exhaust fluid

A more affordable tribometer test (22 May 2018)

In the lubrication industry it is pretty common to have heard of or experienced a lubrication issue due to mixing of incompatible lubricants. Issues encountered include excessive foaming, formation of precipitates or deposits and loss of key performance characteristics such as water separability. Given the gravity of the impact on machine reliability that these issues can cause, there is a demand for testing that can help predict if mixing two lubricants might result in operational issues. Although the lubricants may be deemed equivalent or comparable, that does not mean they are compatible.

Are you having machine failures? Most companies are now realizing that maintaining clean oil is one of the best investments they can make, with contamination at the core of premature machinery failure and diminished lubricant life. A desiccant breather can be used as a first line of defence in preventing contaminants from ruining your equipment.

Ninety percent of lubrication professionals say a lack of attention has negatively impacted the reliability of equipment at their plant.

1. Three basic aspects of lubricating oils

What is lubrication?Lubrication basics

Wikipedia - Lubricant

Lubricants

MRG Labs - Laboratory Lubricant Analyst training (LLA-I) clip

William Kowalski - 6 key factors for lubricant selection

Effects of using a wrong lubricant (2018)

Error-proofing Lubrication (2007)

Jim Fitch - Viscosity starved machines (2015)

David Wedlock - Uninhibited base oils (2017)

David Wedlock - Base oil oxidation (2014)

Oxidation (TOST) test description (Shell Tellus S)

How oxidation occurs (short video)

SKF - Oxidation in hydraulic oil

Antioxidants

Dr Robert M. Gresham - Antioxidants (2018)

Vincent Bouillon - Overview of oxidation laboratory tests on industrial lubricants (first published in Lubes magazine, 2017, 1.3 Mb)

Joshua Jurs, PhD, Global Industrial Oil Technical Manager, Vanderbilt Chemicals LLC - Long term testing of antioxidants for industrial applications (turbine) in Group I and II base oils (first published in Lubes magazine, Feb 2019, 1.6 Mb)

Vincent Bouillon - Oxidation laboratory tests on industrial lubricants (2016)

According to hydraulic component manufacturer Danfoss, if a hydraulic system operates at 85 °C, oil life is just 12% of what it would be if the system operated at 60 °C. And if the system operates at 100 °C, oil life is only 3% of what it would be if the system operated at 60 °C.

Some antioxidants, such as butyl hydroxy toluene (BHT), will turn oil bright red when oxidizing during normal service. While not always cause for alarm, it is clear evidence that the antioxidant is depleting.

Oxidation test RBOTMohammad Naseer Uddin - Misconceptions about RPVOT costing companies millions US$ (2018)

Schaeffer - Oxidation and new requirements for Heavy-Duty Diesel (HDD) oils (2017)

Dr Robert M. Gresham - Rust (2018)

Neil Canter - Metal corrosion preventives: Protect metal and specific applications (2015)

Rust and corrosion

Inhibiting rust and corrosion to prevent machine failures

Understanding the differences between lubricant additives (short with links, 2018)

Dr Nancy McGuire - Sulphur-based additives (2018)

Dr Neil Canter - Metalworking fluids: Update on boundary lubricity additives (2021)

Cortec launches new ashless rust and vapour-phase inhibitor (2022)

tribonet - Density of lubricating oil (2022)/

1.1 Viscosity, kinematic, dynamic, ISO VG

Wes Cash - How to select the best bearing lubricant (11' video, 2021)Dan Holdmeyer - What do HTHS and PSSI have to do with viscosity? (2023)

CSC - Viscosity (2020)

CSC - Viscosity: the basics (short video, 2020)

tribonet - Lubricant viscosity (2021)

Infineum - Specification challenges, e.g.ILSAC GF-6 and the new low viscosity Shield symbol (2023)

Andrea R. Aikin - Lighter grade oils and off-highway vehicles (2021)

tribonet - VI and viscosity caculators (2022)

NiMAC - Calculate viscosity at given temperature

Dr Nancy McGuire - Calculating lubricant viscosity versus temperature (theory, 2021)

Simon Michell - Oil viscosity made simple (2020)

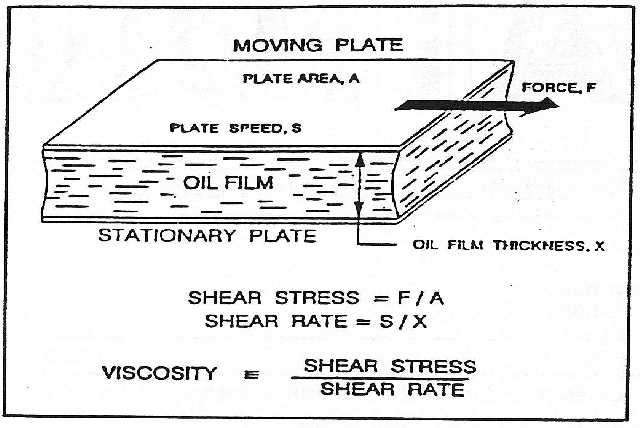

Art Gatenby - Shear stress and shear rate (2020)

Drew Troyer: Kinematic viscosity (2002)

Art Gatenby - What is the difference between dynamic and kinematic viscosity? (2020)

Learn oil analysis - Viscosity of lubricating oils (video 2017)

Dynamic viscosity explained (video 2014)

Parker Kittiwake - Viscosity: A lubricant’s most important characteristic

LE - Viscosity

Oelcheck - Viscosity

Synlube - Viscosity

TLT - Viscosity and types of fluids (2017)

Newtonian vs Non-Newtonian fluids

Art Gatenby - How are consistency, surface tension and viscosity different (2014)

Art Gatenby - A Beginner's guide to surface tension, surfactants and micelles (2022)

Bennett Fitch - Viscometers: A practical guide (2013)

Oil viscosity, how it's measured and reported (2002)

Cannon Instrument - Measuring viscosity of industrial and engine oils (one page, 2017)

Drew Troyer - Understanding absolute and kinematic viscosity (2002)

ISO Viscosity Grades

Dual purpose viscosity-temperature chart (1.7 Mb, blank, suitable for blending)

Viscosity-temperature chart: ISO VG grades(1.8 Mb)

ISO VG limits

Noria - ISO VG limits

Viscosities equivalent: ISO VG and SAE grades

Industrial lubricants (incl. Viscosity guides)

Brendan Casey - Viscosity of hydraulic fluids

Roymech - Viscosity theory

Viscosity, temperature and pressure

Jim Fitch - The meaning of low viscosity (2007)

Gear oil viscosity calculation (theory, 2018)

Viscosity too high, too much lubricant (short video, 2018)

New instrument can test lube film thickness at very high speeds (2022)

Affordable viscosity tester

Parker Kittiwake - Heated viscometer

Spectro - Portable kinematic viscometers

Viscosity is a fluid's characteristic demonstrating its resistance to flow. By definition, unit of dynamic ("absolute") viscosity is the poise, which is defined as the force in dynes required to move a surface one square centimetre in area past a parallel surface at a speed of one centimetre per second, with the surfaces separated by a fluid film one centimetre thick. We commonly use the centipoise (cP) and for kinematic viscosity the centistoke (cSt). There are other methods for determining viscosity, including Saybolt Universal Viscosity (SUV), Saybolt Furol viscosity, Engler viscosity, and Redwood viscosity. Since viscosity varies inversely with temperature, its value is meaningless until the temperature at which it is determined is reported. Viscosity can increase by oxidation and can be reduced by heating through thermal cracking.

Assuming that no water is emulsified in the system, some reasons for an increase in viscosity of a circulating oil might include: the oil may have oxidized; pressure could have increased; temperature might have decreased; possible contamination with a higher viscosity fluid; evaporative losses of light oil fractions from high temperatures; glycol contamination; and soot contamination.

1.2 and 1.3 Viscosity of engine oils and automotive gear oils, SAE, multi-grade

Simon Michell - Engine oil viscosity (2020)Moving to even lower North American engine oil viscosities (2020)

David Wedlock - How base oils can help meet low-viscosity requirements (2015)

Sydney Moore - Can SAE 0W-20 oils protect heavy-duty diesel engines? (2021)

Boris Zhmud - Viscosity matters (2019)

Lubricant must perform and properly flow, even at the coldest temperatures (2018)

JC Motors - Understanding motor oil viscosity

Does thicker oil fix low oil pressure?

Lubrizol - High temperature high shear viscosity test

SAE adds two new grades SAE 8 and 12 to J300

SAE adds light engine oils categories

Ultra-low viscosity engine oils - Go to page 26

Widman - SAE J306 Viscosity classification for automotive gear oils

Brookfield instrument manual

Brookfield: More solutions to sticky problems (2017)

Early discussion about new SAE grades

Japanese race to reduce viscosity

Japanese JASO GLV-1 low viscosity gasoline engine oil specification (short, 2020)

Don't use the North American workshop slang "weight"! It is just as easy to say "viscosity" or "SAE". Lubrication professionals do not use "weight".

When they do, I saw it once or twice, they KNOW that it is WRONG and they do it only because they want to sell you some oil.

In SAE 15W-40, W stands for "winter", NOT "weight".

See comments generated by AI (2023)

Ford recommends using SAE 5W-50 viscosity grade for its GT-500 engine instead of the SAE 5W-20 or SAE 5W-30 used by other engines.

Arup Gangopadhyay

A small increase in lubricant viscosity may be due to the volatilization of base oil "lighter ends" after prolonged high-level operation (i.e. the lubricant has become "thicker"). Significant increases in viscosity up to 20 percent are regarded as severe, caused by incorrect addition of a higher viscosity lubricant, extensive soot contamination and base oil oxidation.

1.4 Viscosity index, viscosity modifiers, viscosity-temperature chart, calculators

Rajiv Taribagil - Next generation viscosity modifiers (2016)David Wedlock dispels a few myths about viscosity modifiers (2018)

Jack Zakarian - Viscosity index too restant to change? (2013)

Trevor Gauntlett - The value of VI (2021)

tribonet - Viscosity index (2019)

Viscosity index (short video)

Wikipedia - Viscosity index

TLT - Viscosity index improvers (2011)

Don't ignore viscosity index (2012)

Viscosity modifiers: A fundamental study

Viscosity index improvers

Eliane Gendreau, Janet Wong - Characterizing the velocimetry of viscosity modifier-containing lubricants in the elastohydrodynamic regime (2022)

Afton - HiTEC 5708A VI improver/Pour point depressant

Chevron Oronite OCP viscosity modifiers

Evonik - Viscosity modifiers

Evonik - VISCOPLEX VIIs for transmission fluids

Functional products viscosity modifiers

Infineum - Viscosity modifiers

Lubrizol - Viscosity modifier calculator

tribonet - VI and viscosity caculators (2022)

Widman - VI and viscosity calculators

A2 size nomogram for viscosity index

Multigrade oils are made by blending a low viscosity oil with special additives called viscosity index improvers. For example, when these polymer additives are blended in the correct proportion with an SAE 15W oil, the oil flows like an SAE 15W oil at low temperatures and like an SAE 40 oil at high temperatures. The result is an SAE 15W/40 oil that will provide wide protection over an extended temperature range.

Applicable range of the above nomogram:

This graph is designed for viscosity indexes between 0 and 100, viscosity of 2-20 cSt at 100 °C, and 6.4-495 cSt at 40 °C. I will publish the wider range graphs (up to VI=200 and viscosity of 2-50 cSt) in near future.

Instruction: This graph has 12 graded lines for viscosity and one for viscosity index. Six lines are nominated for viscosity at 100 and six for 40 centigrade that are paired with letters A, B, C, D, E, and F. To start with the graph:

1. Determine the kinematic viscosity (in cSt) at 100 °C on one of the curved graphs and highlight it with a dot.

2. Determine its paired line using the letters bellow the graph.

3. Find the viscosity at 40 °C on its pair and highlight it with the second dot.

4. Draw a straight line with two dots and using a ruler, and extend it to right hand side to intercept the "Viscosity Index" line.

5. The VI is the interception point of these two lines. You can report it with ±1 accuracy.

6. If you have limitation to measure viscosity at 40 and 100 °C, use ASTM D341 to estimate them.

M. Mahdi Karima

In 1929 Dean and Davis devised a system to express the viscosity/temperature relationship of an oil. The system, viscosity index (VI), was based on the viscosities of base oils obtained from a paraffinic Pennsylvanian crude oil, which was arbitrarily assigned a VI of 100, and base oils obtained from a naphthenic Gulf Coast crude oil, which was assigned a VI of 0.

For diesel engines, the VI additive can be supplied containing another substance, e.g. hydrogenated polydiene, that enhances its performance and also provides better soot handling.

Calculator: Viscosity at operating temperatureCalculator: Viscosity at operating temperature

Calculator: Viscosity at operating temperature

1.7 Viscosity-temperature chart, blending

A proper viscosity-temperature chartVarious viscosity-temperature charts

Widman - Mixing oils

Viscosities of base oil blends (spreadsheet)

1.5 Pour point, pour point depressant

Dr Robert M. Gresham - Are pour point depressants depressing? (2018)David Wedlock - Low-temperature performance of base oils (2014)

Pour_point and pour_point depressants

Wikipedia - Pour point

Evan Zabawski - Pour point (discussion, 2019)

Engineers Edge - Pour_point

Noria - When to use an oil heater (2016)

Oronite - Pour_point depressants

Afton - Pour_point depressants (see video)

Evonik - Pour_point depressants

Oil gelation (2016)

A commonly used rule of thumb when selecting oils is to ensure that the pour point is at least 10 °C (20 F) below the lowest anticipated ambient temperature.

Viscosity is not the only issue associated with high pressure drop across filters on start-up. It might also have to do with the fact that the oil does not have a high enough cloud point. For indoor equipment where filter elements are involved, this can be much more important than the pour point. The cloud point is the point when you can first see wax coming out of solution. If you can see the wax then you know that the filter will also see it. In most cases the wax goes back into solution as the oil warms up. There is generally not a good correlation between cloud point and pour point because pour point depressants (an additive to lower the pour point) enter into the picture.

Ken Brown

1.6 Flash point and Noack volatility

Jim Fitch - How to test flash point (2000)Wikipedia - Flash_point

Noack_volatility_test (but it is done at 250 °C !!)

Noack volatility test: a new set of upheavals (2018)

Flash point and fire point

Volatility of engine oil lubricants in service has become of increasing concern to equipment manufacturers because of oil consumption, engine deposits and air pollution effects. Two types of methods are used to assess volatility: The first is based on simulated distillation by gas chromatography (GCD), and the second, Noack volatility, measures bulk oil weight loss after heating at a prescribed temperature/time.

1.8 Foam, entrained air and air release, defoamant, cavitation

The polar nature of engine oil additives gives rise to their foam-stabilizing properties. The splashing action or the mechanical agitation, or both, of the crankcase oil during engine operation causes air and other vapors to be whipped around, resulting in foam generation. In extreme cases, the oil actually can be lost because of the foam. The entrainment of the air in the oil can also decrease the ability of the oil to provide an effective hydrodynamic lubricating film because of the air bubbles that compromise the integrity of the film.

Defoamants inhibit the formation of stable foams above the oil level in tanks, reservoirs and sumps. Defoamants are typically polymers such as methyl silicone or polymethacrylate. They are dispensed as micro-globules in the oil, around 10 microns in size. These globules are pulled up as the air rises and then weaken the bubbles that form, causing them to burst.

Polydimethyl siloxanes of various molecular weights and are only required at a few parts-per-million concentration to control lubricant foaming. It should be noted that the siloxanes are dispersed in the lubricant in the form of small particles or globules with specialized equipment. These small particles can be seen through the use of a phase contrast microscope similar to that used in clinical laboratories.

Petr Vavruch: Some articles are confusing foam with air entrainment. Don't add defoamant unless you really have to, unless the oil is spewing from the top of the reservoir. Otherwise you spoil the air entrainment.

Morris Bingham - Defoamers (2018)

Dr Neil Canter - Foam (2015)

Wes Cash - Can defoamant additives be filtered? (2016)

Mark Barnes - Air: The forgotten contaminant (2022)

Finding the cause of foam in oil (short, 2019)

Dan Holdmeyer - Air entrainment, aeration, cavitation and foaming: How are they related? (short, 2022)

Is air a contaminant? (2008)

How foam impacts lubricant health (short, 2017)

TestOil - Foaming tendency test

Foaming and air dispersions in industrial gear oils (2015)

More stable foam is due to differential evaporation of the multicomponent base oils (2018)

Air contamination in hydraulic systems (short, 2011)

Marianne Duncanson - Controlling oil aeration and foam (2001)

Causes and solutions for foaming in oil (2008)

Air entrainment, foaming of hydraulic fluids

Dr Nancy McGuire - Air entrainment (2016)

How to control aeration (short video)

Cavitation or aeration: You can hear the difference! (2015)

E. C. Fitch - Cavitation explained and illustrated (2002)

Manoj - Cavitation wear (2022)

Lon Boyson - How to identify and stop pump cavitation (2021)

Dr Neil Canter - Predicting cavitation in hydraulic systems (2021)

Cavitation or aeration? How to tell the difference (2017)

Foaming keeps coming up for discussion

Entrained air in hydraulic oil

How to control oil aeration (short video, 2015)

Learn Oil Analysis - Microdieseling (2018)

Microdieseling and its effects on oil (2012)

Sanya Mathura - Microdieseling: causes, effects and detection (2023)

If foam has traditionally never been a problem but has suddenly started, think about treating not the symptom (the foam), but the cause.

If nothing has changed with the design of the lube system or reservoir, it is likely that this sudden increase in foaming tendency is caused by contamination.

Because foam suppression in a lubricating oil is closely related to the air/oil surface tension, any contamination that can result in either an increase in air entrainment, such as solid particles, or a decrease in surface tension can cause this type of effect. Common contaminants that can decrease the surface tension include water, grease and surfactants, such as soaps and detergents used during machine wash-down.

To diagnose the root cause of your problem, try looking for significant increases in water or particle contamination or the appearance of unexpected elements in your spectrometric analysis data, such as lithium, calcium, aluminum or barium that may signal some other ingested grease or chemical contaminant.

Air contamination can cause a great deal of harm to hydraulic systems. We sometimes overlook this potentially devastating contaminant. Here are a few ways in which air contamination can undermine your reliability effort:

Spongy hydraulics - Air is compressible. This loss of control can slow throughput, increase the percent defective rate, and, in some cases, cause injury or death.

Gaseous cavitation - Some references say gaseous cavitation causes wear, others say it just makes noise. Play it safe and keep as much air out of the oil as possible.

Oxidation - The rate of oxidation is affected by a number of factors, but all else held equal, it is proportional to the amounDefoamants inhibit the formation of stable foams above the oil level in tanks, reservoirs and sumps. Defoamants are typically polymers such as methyl silicone or polymethacrylate. They are dispensed as micro-globules in the oil, around 10 microns in size. These globules are pulled up as the air rises and then weaken the bubbles that form, causing them to burst.t of oil in boundary contact with air (which, of course provides the oxygen).

Thermal degradation - Did you know that compressing an air bubble from ambient pressure to 3,000 psi increases the bubble's temperature to more than 2,000 degrees F? This is hot enough to thermally degrade oil at the boundary contact between the air and the bubble, which darkens the oil, sometimes giving it a sooty appearance causing varnish to build up on component surfaces.

So, watch for signs of air entrainment or foaming, and take occurrences seriously. Also, periodically test your oil's ability to release air and its tendency to maintain stable foam. If you have recurring problems, evaluate the lube specification and the tank design, and check for low levels and signs of a suction line leak.

Drew Troyer, Noria

Air is both a normal ingredient, and a contaminant, of hydraulic oil. It's a normal ingredient because hydraulic fluid typically contains between 6 and 12 percent by volume of dissolved air. There's no avoiding this. And provided this dissolved air stays dissolved, it poses no problem to the hydraulic system or the fluid.

But if this dissolved air comes out of solution or air is ingressed, via the pump intake leak for example, the result is entrained air. These air bubbles are typically less than 1 millimeter in diameter.

Entrained air increases noise levels and decreases the efficiency of the system by reducing bulk modulus (fluid stiffness). And when entrained air bubbles are compressed at the pump outlet, extremely high peak temperatures result.

This compression of entrained air is said to be adiabatic. That is without transfer of heat to the surrounding fluid. However, localized heating of the oil film in contact with the air bubbles results in high-temperature 'cracking'. The result is oxidation and nitration which accelerate degradation of the fluid.

If that's not bad enough, these rapidly imploding air (gas) bubbles hammer the pump's valve plate and other critical surfaces resulting in erosive wear, a.k.a. cavitation erosion.

Prevention is really the only cure. Certain conditions cause dissolved air to come out of solution. When hydraulic oil temperature increases or static pressure decreases, air solubility is reduced and bubbles can form within the fluid. This release of dissolved air is known as gaseous cavitation.

Air can be present in four forms:

- Free air - such as a pocket of air trapped in part of a system.

- Dissolved air - hydraulic fluid contains between 6 & 12 percent by volume of dissolved air.

- Entrained air - air bubbles typically less than 1 mm in diameter dispersed in the fluid.

- Foam - air bubbles typically greater than 1 mm in diameter which congregate on the surface of the fluid.

Of these four forms, entrained air is the most problematic.

Pre-filling components and proper bleeding of the hydraulic system during start-up will largely eliminate free air.

Small amounts of foam are cosmetic and do not pose a problem. However, if large volumes of foam are present, sufficient to cause the reservoir to overflow for example, this can be a symptom of a more serious air contamination and/or fluid degradation problem.

Negative effects of entrained air include:

- Reduced bulk modulus, resulting in spongy operation and poor control system response.

- Increased heat-load.

- Reduced thermal conductivity.

- Fluid deterioration.

- Reduced fluid viscosity, which Userleaves critical surfaces vulnerable to wear.

- Cavitation erosion.

- Increased noise levels.

- Decreased efficiency.

As pointed out above, hydraulic fluid can contain up to 12 percent dissolved air by volume. Certain conditions can cause this dissolved air to come out of solution, resulting in entrained air.

When fluid temperature increases or static pressure decreases, air solubility is reduced and bubbles can form within the fluid. This release of dissolved air is known as gaseous cavitation.

Decrease in static pressure and subsequent gaseous cavitation often occurs at the pump inlet, as a result of:

--Clogged inlet filters or suction strainers.

--Turbulence caused by intake-line isolation valves.

--Poorly designed inlet (diameter too small, length excessive, multiple bends).

--Collapsed or otherwise restricted intake line.

--Excessive lift (vertical distance between pump intake and minimum fluid level).

--Clogged or undersized reservoir breather.

Air entrainment can also occur through external ingestion. Like gaseous cavitation, this commonly occurs at the pump as a result of:

--Loose intake-line clamps or fittings.

--Porous intake lines.

--Low reservoir oil level.

--Faulty pump shaft seal.

Cavitation resulting from a restricted inlet can reduce the service life of a gear pump by more than 50%.

This is quite remarkable when you consider the construction of gear designs make them better able to withstand vacuum-induced forces. The consequences are much worse for piston and vane pumps.

Brendan Casey

Cavitation is the term used to describe the formation of gas cavities within a liquid. In a hydraulic system, this is normally taken to mean formation of vapour bubbles within the oil. But it can also mean dissolved air coming out of solution in the oil.

Cavitation is a violent condition typically in the suction of a pump leading to wear caused by air bubbles or water or oil vapour bubbles.

Cavitation erosion occurs when gas cavities in the oil collapse (implode) under pressure in proximity to a metal surface.

In a hydraulic system, the formation of gas cavities is usually, but not always, associated with the presence of a vacuum (negative gauge pressure).

And the presence of vacuum-induced, mechanical forces can be far more damaging to hydraulic components than pressure-induced bubble implosion.

How many different causes of cavitation in a hydraulic system can you come up with? Here are 20:

Clogged suction strainer (or just the presence of one!).

Wrong fluid viscosity.

Excessively low fluid temperature.

Excessively high fluid temperature.

Defoamants inhibit the formation of stable foams above the oil level in tanks, reservoirs and sumps. Defoamants are typically polymers such as methyl silicone or polymethacrylate. They are dispensed as micro-globules in the oil, around 10 microns in size. These globules are pulled up as the air rises and then weaken the bubbles that form, causing them to burst.

Clogged reservoir breather.

Pump intake line too small (in diameter).

Pump intake drop pipe (inside tank) inlet area too small.

Pump mounted too far above reservoir.

Pump mounted too far from the reservoir.

Excessive pump drive-shaft RPM.

Excessive pump swivel speed (variable displacement units).

Too many bends in pump intake line.

Turbulence caused by intake-line isolation valve.

Collapsed pump intake hose.

Other restriction in pump intake line.

Charge pump wear or failure (closed-circuit HST's).

Excessive internal leakage (closed-circuit HST's).

Faulty or incorrectly adjusted anti-cavitation or load-control valves.

Excessive pressure gradient-decay in working pressure too rapid.

Open return condition.

Whatever the cause, cavitation is detrimental to the long-run reliability of any hydraulic system. Which means tolerating its occurrence is a costly mistake.

So certain conditions can cause this dissolved air to come out of solution, resulting in entrained air.

When fluid temperature increases or static pressure decreases, air solubility is reduced and bubbles can form within the fluid.

This release of dissolved air is known as gaseous cavitation.

Brendan Casey

Return pipes into hydraulic reservoirs should be larger than the intake pipes and should end below the surface of the oil in the reservoir. Locate the return as far away from the suction as possible to allow the oil as much residence time as possible. Better still, install a baffle between the suction and discharge. Cut the return pipe at an angle so that it directs the flow toward the tank wall.

.1.9 Base stocks, saturates, aromatic hydrocarbons, API groups

Infineum - Base stocks (2020)David Wedlock - Residual waxes in paraffinic base stock (2018)

David Wedlock - Catalysts in base stock production (2018)

David Wedlock - Group II base stock (2017)

David Wedlock - Plusses and minuses of highly paraffinic base stocks (2016)

David Wedlock - The effects of aromatics on base stock performance (2016)

Base oils (2016)

David Wedlock - Base oil solvency (2015)

David Wedlock - Base oil feedstocks (2015)

David Wedlock - Bright stock replacement (2016)

Is Bright stock irreplaceable? (2021)

Dr Nancy McGuire - Fundamentals of base oils (2019)

Automotive base oil presentation

Chapter in a book: The evolution of base oil technology

Chapter in a book: Base stocks

Base oils

Crude oil properties and refining process for base oils (8:40 video, 2017)

Understanding base oils (2017)

Lubrication Explained - How are PAO base oils manufactured (video, 2021)

Classification of lubricants

TestOil - API Base Oil Classification explained (2022)

Understanding the differences in base oil groups

David Wedlock - Don't mess up with the API Base Oil Classification (2017)

The fundamentals of mineral base oil refining (2012)

Group II base oils spreading (2017)

Orbichem https://www.lube-media.com/digital-exclusives/- Group I, II and III specifications (example)

Richard Beercheck - Hi VI base oils (2017)

Chevron Group II base oils

Chevron Group II base oils for industrial oils

ExxonMobil base stocks

Consider base oil and refining method when selecting lubricants

David Wedlock - Fischer-Tropsch base stocks (2017)

GTL: Gas to liquids refining

GTL: Gas to liquids produces extremely pure base oils

Biodegradable lubricants (links)

Oil quality is established by the refining processes, and additives are most effective if the oil is well refined. Although the overall performance of an oil can be improved by introducing additives, a poor quality oil cannot be converted into a premium quality oil by introducing additives.

Many of the benefits of high saturates Group II were discovered in use rather than being predicted, such as their much superior dispersant additive response in heavy-duty diesel applications.

Lube oil reclamation and re-refining

Simon Norton - Tricks and traps of oil reclamation (2001)Stephen Chastain - Using centrifugal separators for oil reclamation (2018)

R. David Whitby - Re-refined base oil quality (2015)

Josh Fernatt - Re-refining: Bringing used oil back to life (2013)

Dr Srďan Sokolovič- Re-refining versus recycling waste oils (2021, might require registration)

Valentina Lucchini- Regenerated base oils for a circular and decarbonised lube supply chain (2021, might require registration)

Chinese re-refining process (2017)

Arslan Enginery - Used oil recycling plant

The evolving global bright stock market (2018)

Ergon - Bright stock alternative (VI = 81, 65% paraffinic)

Chinese plant makes Group III+ Bright Stock (21 June 2019)

1.9.1 What does 'synthetic' mean?

Dr Yulia Sosa - PAO and Group III: Industry experts discuss their perspectives, benefits and uses (2022)Oil base stocks (Mobil vs. Castrol on page 8)

What is a true 'fully synthetic' oil?

Petroleum-based mineral oils function very well as lubricants in 90 percent of industrial applications. However, they also have limitations depending on the type of base stock and additives used, the refining technology, and the operating conditions.

PAGs offer the ability to dissolve sludge and deposits, burn without leaving residues when degraded, have a low solubility with hydrocarbons, and have good hydrolytic stability. Their downfall is that they absorb vast amounts of water and have very poor compatibility with mineral and PAO oils.

Esters have a very high detergency and solvency, making them excellent at dissolving sludge and deposits. They are compatible with mineral and PAO oils, and most seal and gasket materials. However, they also absorb moisture from the air and are hydrolytically unstable at high temperatures.

PAOs are most similar to minerals, so they are very compatible. They also are generally compatible with seals and gasket materials. They offer excellent hydrolytic stability, low water solubility and poor solvency. Because of this poor solvency, they should be avoided in applications where high discharge temperatures are present. They have a tendency to form deposits in these situations.

Synthetics - general

Richard Beercheck - Replacing bright stocks (2015)Dr Mathias Woydt, Dr Raj Shah - Future potential framework for synthetic lubricants (2022)

Conventional vs synthetic oil (short article, 2011)

Basics of synthetic oil technology

ExxonMobil synthetics (2015)

Chemours' Krytox - Perflouropolyethers (2017)

Benefits of perflouropolyethers

BASF - Hybrid high viscosity base stock

Methacrylates in combination with Group III in gear oils

Dow Corning - silicones (2017)

Molykote inudstrial lubricants (2007)

Molykote G-900X Series greases for high temperature applications (2017)

The formerly known manufacturer of Molykote lubricants has been Dow Corning, a joint venture between Dow Chemical and Corning Incorporated for over 73 years. In 2016 our parent company Dow Chemical took us over and last year we had a merger with Dupont.

Mathias Sottong

Silicone synthetic lubricants are used when resistance to oxidation, heat and/or water is important and the performance of other types of lubricants is unacceptable. Applications include high-temperature grease and the lubrication of oxygen compressors. Negatives for using silicone synthetics include high cost, poor boundary lubrication and poor additive solvency (they don't accept extreme-pressure and anti-wear additives).

Synthetics - usage

Noria - Synthetic lubricants (webinar, zip file, 2016)Michael J. Raab - On the role of synthetic lubricants in energy efficiency (2014)

Jonathan Trout, Jim Fitch - Synthetic oil: What consumers need to know (2022)

TestOil - Is synthetic oil worth it? (2022)

Pooja Sharma - Growth in the synthetics market chimes with sustainability goals of automotive and industrial end users (2022)

Daniel Rader - Synthetic oil or mineral oil? How to make the right choice (2021)

Seal considerations relevant when switching to synthetics (short)

Mary Beckman - Squeezing energy from synthetics (January 2019)

The estimated improvements for the overall energy savings from a friction perspective only between Group III and PAO are in the range of 0.7% to 1.4%.

SAIT - Financial benefits of synthetic lubricating fluids (2016)AAA report lauds synthetic oils

AAA report (2017, informative)

How true are the performance claims of synthetic engine oils? (2017)

Basics: When to use a synthetic gear oil (short, 2018)

Guidelines for selecting high-temperature lubricants

Synthetic gear oils

Choosing between synthetic lubricants and conventional oils

Advantages of synthetic base oils (2018)

Is synthetic motor oil better for your car? (7 minute video - Answer: Yes)

When does synthetic oil make sense? (short video)

Is synthetic oil better?

Are synthetic lubricants really that good?

PAO-based lubes make machines run cooler (2017)

Mark Barnes - Are synthetic lubricants always a wise choice? (2008)

Selecting oils with high pressure-viscosity coefficient and increase bearing life

LE - When do synthetic lubricants make sense?

Synthetic lubricants for automotive components

Micro-pitting, wind turbines and using synthetics in gears (links)

Synthetic oils have better resistance to ageing and a longer service life, the time between oil changes could be three to five times that of mineral oils. Synthetic oils have improved thermal and oxidation resistance, improved viscosity/temperature characteristics, better low temperature properties and lower evaporation properties. In some instances, synthetic oils have less tendency to form residues.

1.9.2 Polyalphaolefins (PAO)

PAOs have inherently higher specific heats, so it will absorb more heat allowing the PAO-based lubes and the parts that they lubricate to run cooler.

Lubrication Explained - How are PAO base oils manufactured (video, 2021)

Polyalphaolefin (PAO) lubricants explained (2018)

Dr Yulia Sosa - PAO and Group III: Industry experts discuss their perspectives, benefits and uses (2022)

Jeanna Van Rensselar - The bright future for PAOs (2021)

ExxonMobil - Group IV Basestocks: Polyalphaolefins (PAO)

AMSOIL - All synthetics are not created equal

Dodecene-based Synfluid PAOs

Synfluid mPAOs

Mobil 1: True PAO-based synthetic oil

Mobil SHC industrial lubricants (video)

ExxonMobil synthetic fluids and lubricant base stocks

ExxonMobil - Group IV base stocks: PAO

Mobilgear SHC XMP 320 in wind turbines

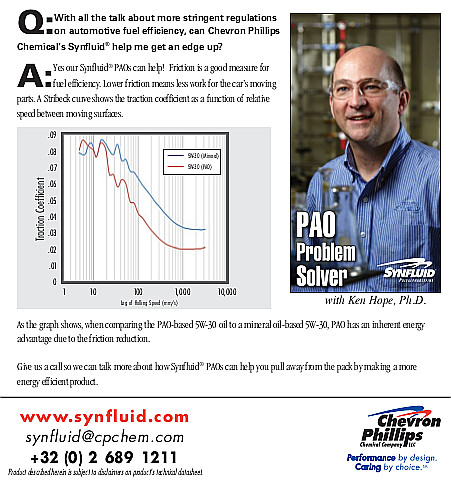

PAO traction advantage

PAO traction advantageOne property that can improve a machine’s efficiency and lessen energy and fuel consumption is known as the traction coefficient. Consider that if you are able to decrease the amount of force required to move a load across a lubricant film, you can reduce the amount of fuel consumed and the number of emissions produced. The traction coefficient is simply the amount of force required to move a load divided by the load. The closer this ratio is to 1, the more force is required to move the load. As the ratio decreases, less force is needed to move the same load.

Mineral oils by nature have millions of combinations of molecular shapes and sizes in each drop. This inconsistency in molecular size results in a higher traction coefficient. Synthetic base oils are manmade compounds and have much more consistency in several key areas, including their fluid properties and molecular size. This allows a load to move more easily across the lubricant film, thus lessening energy consumption and emissions.

To envision how this works, imagine pushing a sheet of plywood across a series of balls. If the balls are different shapes and sizes (footballs, basketballs, baseballs, etc.), moving the piece of plywood becomes more cumbersome and awkward. Now if you took that same sheet of plywood and pushed it across a series of tennis balls, with each ball the same shape and size, it becomes much easier. This is why most synthetic oils come with claims of reducing energy consumption and can actually help to decrease emissions.

Food-grade lubricants (Beyond the scope of the book)

MOSIL - Frequently asked questionsRichard Beercheck - Formulating food safe lubricants (2016)

Do you know the difference between H1, H2, H3, 3H and other food-industry lubricants? (2015)

Loren Green - Understanding the changing requirements for food-grade lubricants (2017)

Ashlee Breitner - International food safety standards and regulations (2014)

Loren Green - Food processing lubrication: 7 critical items for success (2021)

Saurabh Lawate - What you need to know about food-grade lubricants (2007)

Sabrin Gebarin - The basics of food-grade lubricants (2009)

Jim C. Fitch, Martin Williamson, Sabrin Gebarin - Industrial food-grade lubricants guide (2009)

Dr Holger Streetz - How to avoid mineral oil contamination in food processing (2020)

Jane Marie Andrew - Safer lubricants for food processing equipment (2022)

Harshvardhan Singh - Food-grade lubricants (2022)

Sushmita Dutta - Food-grade lubricants (2022)

Spotlight on food-grade lubricants (2021)

Caitlin Jacobs - Upping the ante on food-grade lubes (6 May 2020)

Dr Nancy McGuire - Incidental contact lubricants for the food industry (2019)

Food-grade lubricants

Advantages of food-grade lubricants (2012)

Martin Williamson - Food-grade lubricants explained (2003)

NSF certified 'food-grade' lubricants

MOSH and MOAH dangerous?

ELGI - The selection and usage of food safe lubricants

Lubriplate - The continuing evolution of food grade lubricants

Jim Girard, Lubriplate - H-1/Food grade lubricants (2015)

PAG food-grade lubricants

SKF introduces food-grade lubricants

Evonik - Viscoplex 8-219 VI improver for hydraulic fluids registered by InS Services as HX-1 ingredient for H1 lubricants with incidental food contact

Chevron FM grease does not perform as well as conventional greases in terms of rust protection (2008)

The United States Department of Agriculture (USDA) created the original food-grade designations H1, H2 and H3.

H1 lubricants are food-grade lubricants used in food-processing environments where there is the possibility of incidental food contact.

H2 lubricants are food-grade lubricants used on equipment and machine parts in locations where there is no possibility of contact.

H3 lubricants are food-grade lubricants, typically edible oils, used to prevent rust on hooks, trolleys and similar equipment.

R. Auerswald

1.9.3 Other synthetic hydrocarbons

Alkyl benzene as a compressor lubricantAlkylated naphthalenes

King Industries - Alkylated naphthalenes (2017)

Anuj Kumar - Polyisobutylene market (2019)

Polyisobutylene

TPC Group - Polyisobutylene

BASF - Polyisobutylene

1.9.5 Polyalkylene glycols (PAG) (polar compounds)

PAG synthetic oilPolyalkylene glycols

Polyglycols for lubricating large gear drives

Friction and wear reduction mechanism of polyalkylene glycol-based engine oils (2018)

Polyalkylene glycol - synthetic turbine fluid technology

Turbine lubricants: biodegradable, preventative alternatives

Synthetic gear oil selection - See wear of aluminium components

New synthetic OSPs for high performance greases

Klüber: Changeover from mineral oil/polyalphaolefin to polyalkylene glycol

Ucon OSP - oil soluble PAG

Oil soluble synthetic polyalkylene glycols

Innovations in PAG based lubricants

Energy efficient industrial gear lubricants

Sullube - Laboratory analysis of PAG in service

Heat of combustion, flash point, autoignition temperature of PAG

Effects of water on PAG (2009)

Removing water from PAG

Worm gears (links)

This is a simple test to verify that an oil is a polyalkylene glycol (PAG), a fluid commonly used in brake systems, compressors and some gearboxes. Mix a small sample of the fluid in question with a mineral-based turbine oil. If it fails to blend into the turbine oil, it is probably a PAG

Sludge and varnish in hydraulic controls of turbines is not a problem with PAG turbine oils owing to their high solubility. However, some PAG turbine oils cause sudden oxidative degradation, resulting from a decrease in anti-oxidants due to poor thermal stability of those PAG base oils.

1.9.6 Esters, amides, environmentally friendly lubes

Tyler Housel - Synthetic esters: Engineered to perform (2011)Esters (2017)

Dr Mathias Hof - Esters (2016)

Novel hybrid esters: Base oils designed for sustainability

Martin Greaves, Zach Hunt, Jeffrey DiMaio - Novel hybrid esters: Base oils designed for sustainability (2023)

Rapeseed natural ester fluid for Extra High Voltage transformer (2020)

Cargill natural ester fluid for South African electrical grid (2020)

Schaefer - Esters in synthetic lubricants

Schaefer - Esters in synthetic lubricants

Synthetic esters

Inolex - White papers on esters

Wikipedia - Polyol esters

Hydrolytic stability: an important parameter to balance (2022)

Rexroth - List of environmentally acceptable hydraulic fluids

Croda Lubricants to launch new Group V base oil technology (amides)

Emery Biolubricants (Esters)

Environmentally friendly lubes for marine use (2017)

Erlend Hanssen Nervold - Ensuring satisfactory aft stern tube bearing lubrication performance (3.1 Mb, 2019)

Erlend Hanssen Nervold - Natural ester oil application in liquid filled transformers (3.3 Mb, 2019)

Dr Hermann Josef Stolz, Dr Wilhelm Huber, Dr Martina Mennicken-Meuthen and Denise Weber - Seal material compatibility

Phosphate esters (links)

Vegetable oils and biodegradable lubricants (Beyond the scope of the book)

Biomass process (picture)Richard Beercheck - Biodegradability: Which test is best? (2014)

Dr Neil Canter - Biodegradable lubricants: Working definitions, review of key applications and prospects for growth (2020)

Mary Beckman - The additives equation: Biobased oil stocks serve up different chemical qualities (2020)

David Wedlock - Biodegradation in base oils (2017)

Oil flushing techniques for converting to biodegradable fluids (2012)

Spotlight on bio-based lubricants (2021)

Brajendra K. Sharma, Sevim Z. Erhan, Raj Shah, Blerim Gashi, Nicole Turner, Gobinda Karmakar, Pranab Ghosh - Vegetable oil-based additives for lubricant formulations (2022)

Jeanna Van Rensselar - Biobased base stock (2021)

Guillaume Notheaux, Marie Legatte - SEQENS calcium sulphonate biodegradable greases (2021)

Erik Willett - Water-soluble thickeners for industrial and ecofriendly lubrication (2020)

Are biobased lubricants food for microbes? (2018)

Biodegradable lubricants (2012)

Improving vegetable oil properties for lubrication

Biodegradable oils - How to apply and maintain

Controlling degradation in biodegradable greases

New test methods for lubricant biodegradability

Proposed ASTM biodegradable hydraulic fluid standard

Vincent Bouillon, BfB Labs - Assessment and verification of environmental acceptable hydraulic fluids (EAHF) according to the European Ecolabel’s revision, Part 2 (2019)

What you should know about environmentally friendly lubricants

Using biodegradable oils, for example, is the growing response to potential leaks in farm equipment.

Although these new lubricants and fluids are better for the environment, they can also wreak havoc on traditional seals. These liquids frequently contain aggressive compounds that weaken and break down elastomer bonds in standard sealing materials.

Christian Dickopf

1.9.7 Naphthenics

Nynas - Base oil handbookNynas - Group I replacement with naphthenics

Nynas - Naphthenic oils for greater efficiency

Nynas - Anti-oxidant response of low sulphur naphthenic base oils (2017)

1.10 Oil performance, performance additives

Infineum - Are all lubricity products equal? (2019)ATC (Jacqueline Berryman) - Lubricant additives: Use and benefits (2016)

Dr Yulia Sosa - Finding the balance in additive performance (2022)

Dan Holdmeyer - How additives finish the lubricant (short, 2022)

Dan Holdmeyer - More about additives finishing lubricants (2022)

Additives in lubricating oils

The chemistry and function of lubricant additives (2017)

Dr Robert M. Gresham - The mysterious world of lubricant additives (2012)

The contributions of additives

Lubrizol - Lubricant fundamentals 2: additives (video, introduction in end Part 1)

Formulations of lubricating oils

Additives

Lubricant additives

Noria - A practical guide to lubricant additives (comprehensive, 2018)

Dr Neil Canter - Sulphurized additives: Types available, key applications and beneficial properties (2019)

Infineum - Additives (2017)

The truth about additive depletion (video)

The critical role of additives in lubrication (2012)

How to determine the quality of a lubricant additive

Dr Robert M. Gresham - Detergents and dispersants (2018)

Rhein Chemie additives

Don Smolenski - What’s up with ionic liquids? (2021)

ZDDP (links)

Neither mineral nor synthetic base oils can satisfy today’s lubricant performance requirements without using additives. Additives are chemical substances, in most part synthetic, which are used in lubricant formulations to adjust a broad of spectrum of properties by enhancing what is desired and suppressing what is unwanted. Many additives are multifunctional products that may exhibit synergistic or antagonistic behavior when mixed together. As a rule of thumb, additives do not add. This makes balancing and optimization of additive systems a challenging task.

1.11 Water separability (demulsibility)

Hi-Pro - What is demulsibility (2 pages, 2022)Hi-Pro - Getting to know demulsibility (short, 2021)

Jennifer Yeadon - Steam turbines and the battle for good demulsibility (2019)

Hi-Pro - Demulsibility (video, 2019)

The importance of demulsibility in oil

TestOil - Demulsibility

Water separability

Test Method for Water Separability

Demulsibility ASTM D 2711

1.12 Supplemental ('proprietary') additives

Pros and cons of enhancing your oil with additives (short, 2019)Advice for improving oil with additives (2012)

The disadvantages of using anti-friction metal conditioners

The advantages of lubricant conditioners

How engine cleaners affect your oil

Blue exhaust smoke indicates an engine is headed for serious mechanical failure due to a high oil ingress into a combustion chamber. This means an engine is burning too much oil due to worn intake valve guides or poor piston ring control – collapsed or worn rings.

A useful rough guide to measuring oil consumption is the ratio of oil consumption to fuel consumption, because the harder an engine works (fuel consumption) the more oil it will use. A good estimate is 0.6% of total fuel consumption.

REVISION 1

Answers to REVISION 1 (link)3.1 Engine oils, engine oil additives, ZDDP, fuel economy

Dan Holdmeyer - Additives and engine oils (2022)Engine oils and their filters (2018)

Richard Widman - How do I understand different engine oils? (2018)

Kiara Candelaria - Reliable wear protection in ultra-low-viscosity oils (2018)

Dr Raj Shah, Dr Mathias Woydt, Isaac Kim - Maximizing fuel economy by thinning lubricating oils (2020)

Engine oil specifications

What is the best oil for my car (2018)

Dr Nancy McGuire - The drive for efficient performance (2018)

Engine oil quality (2015)

Spectro Scientific - Webinar: Engines 101, Understanding basic engine operation

Engine oils

Does thicker oil fix low oil pressure?

Lubrication system: Engine oil functions (video)

Low speed pre-ignition (2019)

Selecting the correct lubricant

Wikipedia - Motor oil

Jeremie Edwards - High mileage oil: a practical guide (2019)

AMSOIL - European motor oils and SAPS content (2018)

Michael C. Brown - Engine oil differences (2016)

Jim Fitch - Four lethal diesel engine oil contaminants (2007)

Dr Robert M. Gresham - Detergents and dispersants (2018)

Peter Wright, INFINEUM - The art of dispersant design (2018)

Friction, lubricants, energy losses, tribo tests, engine oils, base oils, additives, coatings

Passenger car engine oil change intervals: past, present and future (2018)

Additives boost fuel economy

Friction and wear reduction mechanism of polyalkylene glycol-based engine oils (2018)

Dr Neil Canter - ZDDP's uncertain future (2019)

Steve Swedberg - ZDDP: Why? How? How much? (2014)

The anti-wear additive zinc dialkyldithiophosphate

Certain amount of ash in the lubricant is needed to increase the filtration efficiency of the gasoline particulate filter (2019)

Zinc phosphate reaction with iron oxide

Trevor Gauntlett - Will ZDDP ever be replaced? (2022)

Joanna Dawczyk et al. - Film thickness and friction of ZDDP tribofilms (scientific paper, 2019)

History of ZDDP

BASF - IRGALUBE FE1 - Save fuel by interacting with ZDDP (2017)

Dr Wilfred T. Tysoe, Dr Nicholas D. Spencer - ZnDTP alone as a primary suspect in the formation of white etching cracks (2019)

Lisa Tocci - White etching (2018)

Elco ZDDPs

Toyota - Better antioxidants, higher quality base oils to prevent turbocharger coking

New low viscosity grade engine oil specifications in Japan

Antifreeze contamination in motor oil (short video)

ZDDP reaction films formed on rubbing contacts produce enhanced friction in mixed lubrication conditions. The ZDDP reaction film appears to inhibit lubricant entrainment into the contact, thereby leading to a reduced EHD film thickness compared to ZDDP-free lubricants.

Turbocharged gasoline direct injection (TGDI) engines suffer from the presence of particulates in vehicle exhaust emissions, similar to a diesel engine. New oil specifications are needed to counter that.

There are many different quality oils on the market.

At the starting level, we have many brands sold by the dollar stores and convenience markets that are very basic, cheap base oil with minimal, cheap additives. They may or may not pass the API tests, and probably are not registered (so don’t have the Donut and starburst.

Then you have four levels. Look for a moment at big brands. Castrol (as an example) has an entre level GTX that meets the minimum API standards when new and for the minimum time for certification. Then they have Magnatec, which is a much better blend of base oils and a better package of additives. They also have two different synthetic oils, one for price point, made with Group III base oil, and one with traditional PAO synthetic base oil.

Most of the big brands do something along the same lines. I used to carry only the second and fourth (a great semi-synthetic, similar to the Magnatec, and a great PAO/Ester synthetic, similar to Mobil1). About 2 years ago, I started to add the 3rd level (group III synthetic) for people who insisted on synthetic but would go to Castrol for the cheaper product. I am phasing this one out, as once people try the real PAO synthetic, they are not satisfied with the cheaper version.

Richard Widman

Friction, wear and failures (Beyond the scope of the book)

Noria - Friction and energy saving (webinar, zip file, 2015)Hugh Spikes - Friction modifier additives

Paul Farless - Understanding friction and friction modifiers (2021)

tribonet - Friction of materials (2022)

tribonet - Adhesion: Definition, theory and types (2022)

Andrea R. Aikin - The tribology of piston rings and why it matters in an electric vehicle world (2023)

tribonet - Friction (2016)

tribonet - Stribeck curve (2021)

Dan Holdmeyer - The Stribeck curve (2022)

Wikipedia - Friction

Castrol - Friction reducing technologies: Fact or 'Friction'

Friction and traction

Rolling friction

Friction theory

tribonet - Droplet friction is similar to solid friction (2017)

How to reduce friction between surfaces (short)

Paul Farless - Friction modifiers (2021)

Friction modifiers

Friction modifiers (2015)

Jeanna Van Rensselar - Vanishing friction—also called superlubricity (2022)

Superlubricity (2017)

Tribological design guide part 5: Wear theory

Wear theory

Learn Oil Analysis - What is the difference between normal and abnormal wear (2019)

Researchers simulate wear of materials as they rub together (2016)

Basics of wear

Matthew Adams - Adhesive wear (2020)

Abrasive wear (short)

Wes Cash - Polishing wear (2018)

Fretting wear (2021)

tribonet - Fretting wear (2018)

Dr Yulia Sosa - False brinelling: An increasing type of a rolling bearing wear (2023)

Cavitation (links)

Wear = the silent killer

Randy Riddell - The keys to solving fatigue, the silent killer (2019)

Premature wear (short)

Three common contaminants and the oil analysis tests that can detect them

Robert Scott - Basic wear modes in lubricated systems (2008)

Ray Garvey - Why machines fail and what you can do to prevent it (2023)

John Cummins - Failure mode and effects analysis (2016)

Common causes of machine failures

Types of engine bearing damage

Main bearing failure chart

Gear failures (links)

Rolling element bearing failures (links)

Bore glazing and polishing in diesel engines

Dangers of electrostatic discharge in engine oils (2015)

All machines wear out eventually. The key is to delay the inevitably. So with this objective in mind, here are 6 different ways hydraulic components lose their life:

1. Abrasive wear is the scuffing and scoring of a lubricated surface. It can be further divided into two-body abrasion and three-body abrasion. Two-body abrasion occurs when two lubricated surfaces come into direct contact with each other-usually as a result of loss of the lubricating oil film. Three-body abrasion occurs when the clearance between two lubricated surfaces is bridged by one or more hard particles. In this case it's the clearance-sized hard particles that are responsible for scoring the lubricated surface(s).

2. Adhesive wear is usually a progression of two-body abrasion. If the oil film between two lubricated surfaces moving relative to each other is lost, the two surfaces begin to scuff (two-body abrasion). This scuffing results in friction which creates heat. If the friction and heat is sufficient, the two surfaces can begin to adhere (friction weld) to each other. Although complete seizure is possible, adhesive wear typically results in the transfer of metal from one surface to the other, as the asperites (microscopic high points) adhere and are then torn from their parent-metal surface.